Trending Assets

Top investors this month

Trending Assets

Top investors this month

How to build a greener energy future

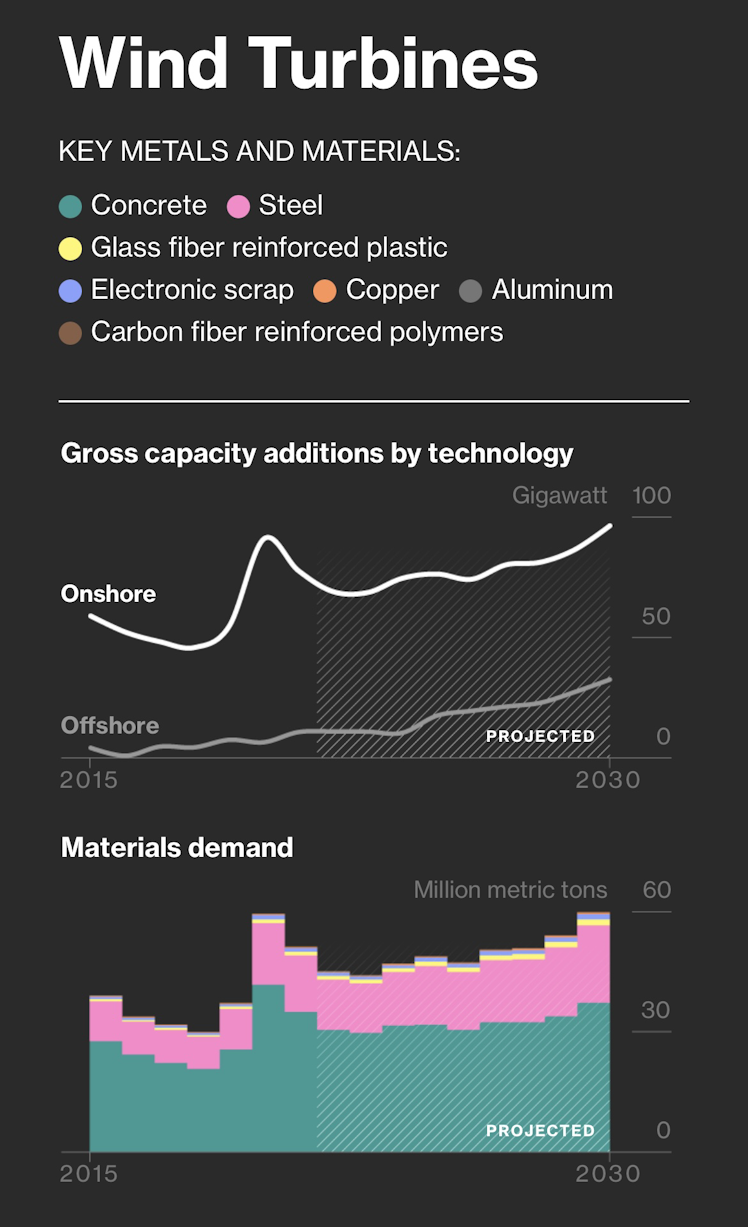

Today 1.2 PWh of wind energy is produced. To meet 2050 climate goals we need to be at 5 PWh of wind by 2030.

69-77% of turbine mass is steel. 11-16% fiberglass/plastic. 1% aluminum and 1% copper.

The base of the turbine is concrete and rebar.

Each new MW of wind power requires 120 to 180 tons of steel.

20 million tones steel per year needed to build wind turbines today which will grow to 25 mil tones steel by 2030.

Steel is a metal alloy of iron, carbon and other metals. Increasingly Vanadium is being used to strengthen steel and rebar.

92% of current Vanadium mined today is used for steel production. Adding vanadium to steel increases strength and decreases weight.

As wind turbines continue to get larger more vanadium will need to be used to strengthen the steel. Mixing titanium with vanadium and iron makes wind turbines able to spin up to 70,000 rpm. The concrete bases will also need to be stronger to hold larger turbines. Projections of 6% yoy annual increase in Vanadium will be needed for rebar alone.

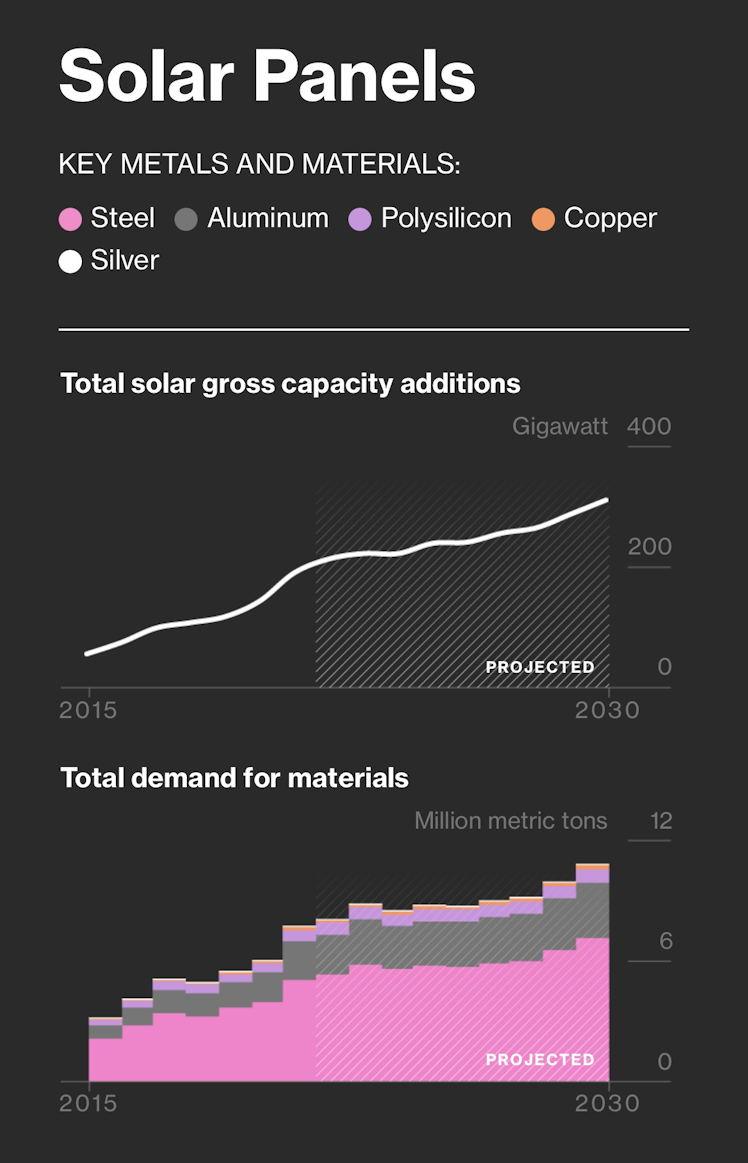

6 million tones steel/year for solar

All of that is just a bonus. Vanadium’s real future value as an essential element is all about battery storage. Specifically Vanadium flow batteries. VFB seem like the most obvious cost effective solution to renewable energy storage. Cost effective energy storage is essential bc most renewable energy is intermittent (wind, solar, hydro).

Still researching my favorite way to play the Vanadium future. Currently looking into miners or vanadium flow battery producers.

@jennymanydots Vanadium Cassandra sounds like a super hero. I like the name change

Already have an account?